Description

1. Characteristics of PTFE(UHMWPE)Ram Rod Extruder PFB20

- Through continuous improvement, the equipment is smarter, more stable and more efficient.

- The equipment is controlled by PLC system, and operated automatically with simple operation.

- With diverse design, the equipment can meet the different needs of users, and be customized for customers.

- The equipment runs stably for a long time, with lower noise. And reduces costs by saving power and energy during pressure maintenance.

- Equipment and molds are made by special technology, corrosion resistance, durable and with long service life.

- The equipment design is simple and takes up little space.

- Extruded products have superior performance in terms of density and tensile strength.

- Equipped with an automatic feeding system, filling a bucket of 50-80 kg, automatic feeding system can guarantee 4-8 hours of operation and save labor costs to a great extent.

- PTFE ram rod extruder can continuously push rod and the rod can be cut according to the requirements.

- Provide a complete mold system, which includes a full set of corresponding accessories, heating and sintering system, cooling system, temperature controller, bracket, etc.

- The vertical rod extruder extrude from top to bottom. The equipment can be placed on the second floor or a platform.

2. Equipment Operating Environment Requirements

- The ground of the site is required to be level, and the site load is not less than the design requirements.

- The operating platform needs clean space to reduce dust ingress. It is best to have ventilation ducts in the workshop to facilitate ventilation.

- Industrial power standard 380V 50Hz 3P, voltage can be customized according to user needs.

- The factory is equipped with power distribution cabinets, compressed air and other supporting equipment.

- The equipment needs to be equipped with a cooling system. Two buckets / water tanks can be used with a cooling pump to recycle water resources.

- The room temperature of the plant should be no more than 28 ° C.

- The vertical extrusion equipment extrudes from the top to the bottom. The equipment is installed on the platform or floor with a space height of about 2.8 meters. The effective distance in the longitudinal direction of the device needs to be considered, and a sufficient height must be guaranteed under the fixed circular hole of the device to meet the requirements of the length of the extruded PTFE rod.

- Horizontal extrusion equipment needs to consider the effective distance in the horizontal direction of the equipment, and it is necessary to ensure the length of the PTFE rod. The equipment includes a mold length of 4-7 meters (excluding the length of the extruded finished rod), a width of 1.2 meters, a height of 1.8 meters.

3. Equipment Parameter

| Machine Model | PFLB20 | PFB80 | PFB150 |

| Process | Vertical Extrution | Horizontal Extrution | |

| Power KW(Electric Motor) | 14 | 24 | 33 |

| Rod Range Dia(mm) | 4-20 | 25-80 | 80-150 (200 ) |

| Extruded Rod Length | Continue extrude with unlimited length | ||

| Controller | PLC+Touch Screen | PLC+Touch Screen | PLC+Touch Screen |

| Output(Kg/h) | 7+ | 8+ | 10+ |

| Voltage/ PH/Hz | 380V 50Hz 3P | 380V 50Hz 3P | 380V 50Hz 3P |

| Electricity Consumption(KW/h) | 2+ | 2.5+ | 3+ |

| Temperature zone | 3-5 | 4-8 | 8-12 |

| Machine Weight(Kg) | 930 | 960 | 1220 |

| Machine Height (mm) | 2150 | 1800 | 1900 |

| Machine Floor area (m2 ) | 3.5 | 7 | 10 |

| Mold | The mold size is customized according to customer specifications. The complete mold set includes the mold body, extrusion head, connection flange, a complete set of high-temperature heating rings, a complete set of sensors, a cooling water jacket system, and the high-temperature connection line, mold and product support.The surface finish is specially treated to be smooth, durable, and corrosion resistant. The thickness of the insulation cotton is more than 5mm, and the heating thickness is more than 10mm. | ||

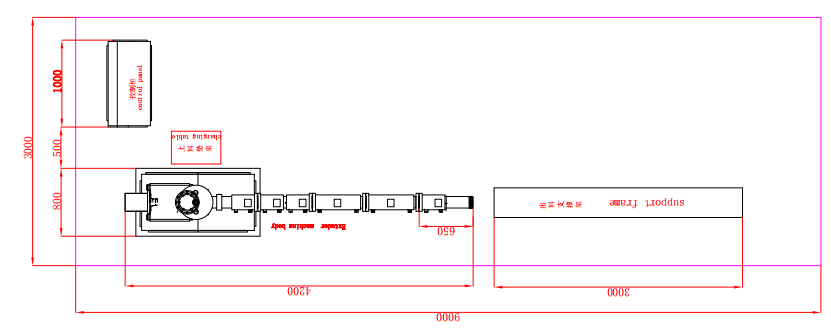

4. Equipment Installation and Mold Installation Diagram

5. Equipment And mold Maintenance

- Regularly check the height, cleanliness and temperature of the hydraulic oil.

- It is recommended to replace the hydraulic oil every six months.

- Replaced worn seals timely.

- The mold should be cleaned and maintained in time, and the surface should be coated with a thin layer of protective oil.

- Carefully handle the temperature sensor of the heating coil, and store it properly.

6. Accessories And Spare Parts Description

- The equipment is composed of main machine, a hydraulic station, a control cabinet, an automatic feeder, holders, heating cavities, molds and other accessories. Equipment necessary accessories are sent to customers with the equipment.

- The list of necessary accessories for the equipment is sent to the user with the equipment.

- When the user purchases our company’s equipment, in addition to the necessary accessories, we will provide the necessary spare parts to the user to replace and repair the equipment. Spare parts are standard parts and can be purchased in the local market.

-1.jpg)

Reviews

There are no reviews yet.